About 2-5 Ton Per Hour Industrial Chakki Atta Plant

Industrial chakki atta plant is a large scale pulverizer system that is commonly used for grinding wheat grains and other food products. It is fully automated in operation and requires a standard alternating voltage of 440 volts with a frequency of 50 to 60 Hertz. The motor installed within this unit has a rated power of 150 horsepower, which is capable to run efficiently for a longer period. The offered Industrial chakki atta plant comes with a warranty of 12 months. It is capable of producing processed materials with a capacity of 10 to 300 tons per day.

Robust Design and AutomationCrafted from corrosion-resistant galvanized steel, the chakki atta plant is built for longevity and high performance. The automatic grade, paired with PLC control, streamlines flour production, reducing labor dependence and possible errors, while enabling precise management of operational parameters.

Optimal Production CapacityDesigned for continuous operation, the plant processes between 1 to 4 tons of wheat per hour. This capacity suits medium to large commercial users seeking consistent flour output to meet growing demand, handling bulk production efficiently and reliably.

Comprehensive Warranty and SupportThe industrial chakki atta plant includes a 12-month warranty, providing assurance and support to users. Manufacturers, suppliers, traders, and wholesalers in India benefit from dedicated after-sales service and accessible technical assistance to maximize uptime and minimize disruptions.

FAQ's of 2-5 Ton Per Hour Industrial Chakki Atta Plant:

Q: How does the PLC control system enhance the performance of the industrial chakki atta plant?

A: The PLC control system automates the milling process, enabling precise adjustment of production parameters. This reduces human error, ensures consistent flour quality, and increases overall productivity in commercial environments.

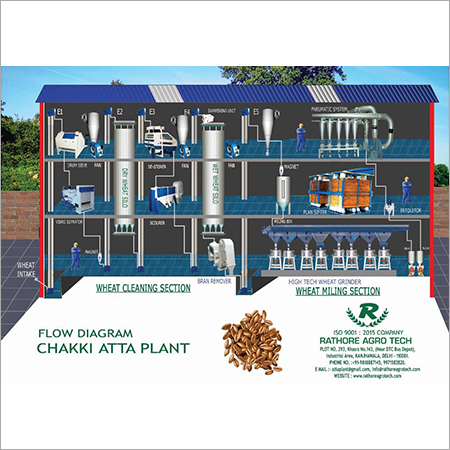

Q: What is the typical process flow for wheat in this chakki atta plant?

A: Wheat is fed into the plant, where it undergoes cleaning, grinding, and sieving. The automated system handles each stage efficiently, producing fine atta flour ready for commercial packaging or further processing.

Q: When should the plant be serviced to maintain optimal operation?

A: Regular maintenance should be performed as recommended by the manufacturer, typically every three to six months. Additionally, users should follow the guidance provided during the initial installation and consult the warranty terms for specific service intervals.

Q: Where is this industrial chakki atta plant most commonly used?

A: It is widely used in commercial flour mills, food processing facilities, and bulk supply operations. The plant is especially suitable for manufacturers, suppliers, traders, and wholesalers across India seeking high throughput and reliable performance.

Q: What are the benefits of using galvanized steel in the construction of the atta plant?

A: Galvanized steel provides strong resistance to corrosion and wear, extending the operational life of the plant. It also ensures hygienic milling conditions, meeting safety and quality standards for food-grade equipment.

Q: How does using this automated chakki atta plant improve efficiency?

A: Automation minimizes manual intervention and speeds up the production process, allowing users to handle larger volumes of wheat efficiently. Consistency in flour quality and reduced downtime are key advantages for commercial users.