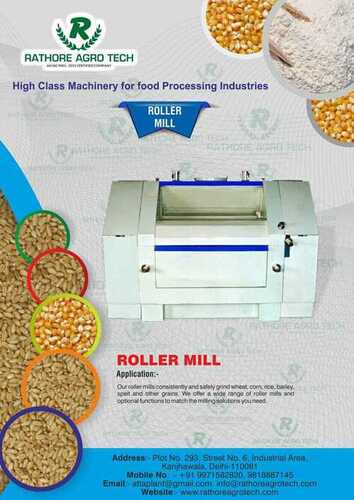

About 3 Ton Per Hour Roller Flour Mill

We are offering an extensive series ofRoller Flour Mill.These products are extremely employed in the market for diverse purposes.

Product Description:

- Pulverizer is used for coarse and fine grinding with standard mill for fariable materials in a single unit. Pulverizer designed for spices, cattle feed plant, pulverizers use in flour mill for refraction grinding & daliya cutting. It also used in besan plant. Material which are pulverized by the pulverizer bullet Wheat Spices Pulses Coffee Seeds Coal Zinc oxide Plaster of paris Glue Malt Tobacco Soya bean Corn Cereals Mullein Animal feed Herbs Chemicals & pharmaceuticals etc.

Superior Milling EfficiencyEngineered for high-capacity operations, this roller flour mill processes up to 3 tons of grain per hour, ensuring smooth throughput for commercial demands. With its automatic features and variable speed, your flour production is both efficient and adaptable to different grains or requirements.

Built to Last with Best Quality MaterialsDurability and hygiene are crucial in flour processing. Thats why this mill is constructed from premium stainless steel and designed with a sleek white finish. Its resistant to corrosion, easy to clean, and maintains product purity, making it a valuable long-term addition to any setup.

FAQs of 3 Ton Per Hour Roller Flour Mill:

Q: How does the automatic roller flour mill enhance commercial flour production?

A: This flour mill automates key milling processes, ensuring consistent quality and reducing manual intervention. Its 3-ton-per-hour capacity allows for large-scale, efficient production, making it ideal for commercial enterprises seeking to optimize output and minimize operational effort.

Q: What is the installation process for this roller flour mill?

A: The flour mill uses a free-standing installation type, which means it can be placed directly on the factory floor without the need for complicated mounting or structures. Basic positioning, electrical connection to a 3-phase supply, and routine safety checks are recommended during setup.

Q: When is computerized control necessary, and how does this mill operate without it?

A: While computerized control can offer more automation, this mill utilizes a manual control system supplemented by automatic features. For most commercial uses, the combination provides ample efficiency and control, with no need for added complexity of computerized systems.

Q: Where is the ideal location for installing this roller flour mill?

A: It is best suited for commercial milling environments, such as food processing factories, wholesale bread manufacturing units, or grain trading facilities across India. Proper ventilation and stable electric supply are recommended for optimal performance.

Q: What is the process for milling with this system?

A: Simply load grains into the feeding system; the machines rollers automatically grind the grain to flour, which is then collected via discharge outlets. Operators can adjust speed and monitor output for the desired fineness and quality.

Q: How should the roller flour mill be maintained for best results?

A: Regular cleaning and inspection of the stainless steel rollers, checking for wear, and ensuring proper electric supply help maintain peak performance. Periodic maintenance ensures long-lasting operation and consistent quality results.

Q: What are the main benefits of using this automatic roller flour mill?

A: Users benefit from high-capacity, reliable flour output, user-friendly manual control, robust stainless steel construction, and streamlined operations. Its automatic functions reduce labor costs and the risk of human error, making it a cost-effective choice for expanding commercial setups.