About Centrifugal Fan

Die cast aluminum made Blower is used as integral equipment in food processing field. Driven by electricity, this machine has IP55 protection rating. With having F class insulation rating, this machine is appreciated for its high speed operation. It consists of necessary parts like blow and suction vacuum, compressor and burst proof motor. This equipment is reckoned for its energy efficient operation, compact shape, maintenance free functioning and low noise operation. It has standard pressure level, vacuum range and air flow level. This machine has low downtime rate and it is quite easy to operate. We are a successful trader and manufacturer of Blower.Advanced Automatic Operation for Industrial DemandsThis centrifugal fan is designed for automatic use in demanding industrial environments, particularly roller mills. The PLC control system ensures accurate operation while requiring minimal manual intervention. With capacities ranging from 500 to 6000 kg/day, it is ideal for wheat processing, enhancing productivity and efficiency throughout your milling process.

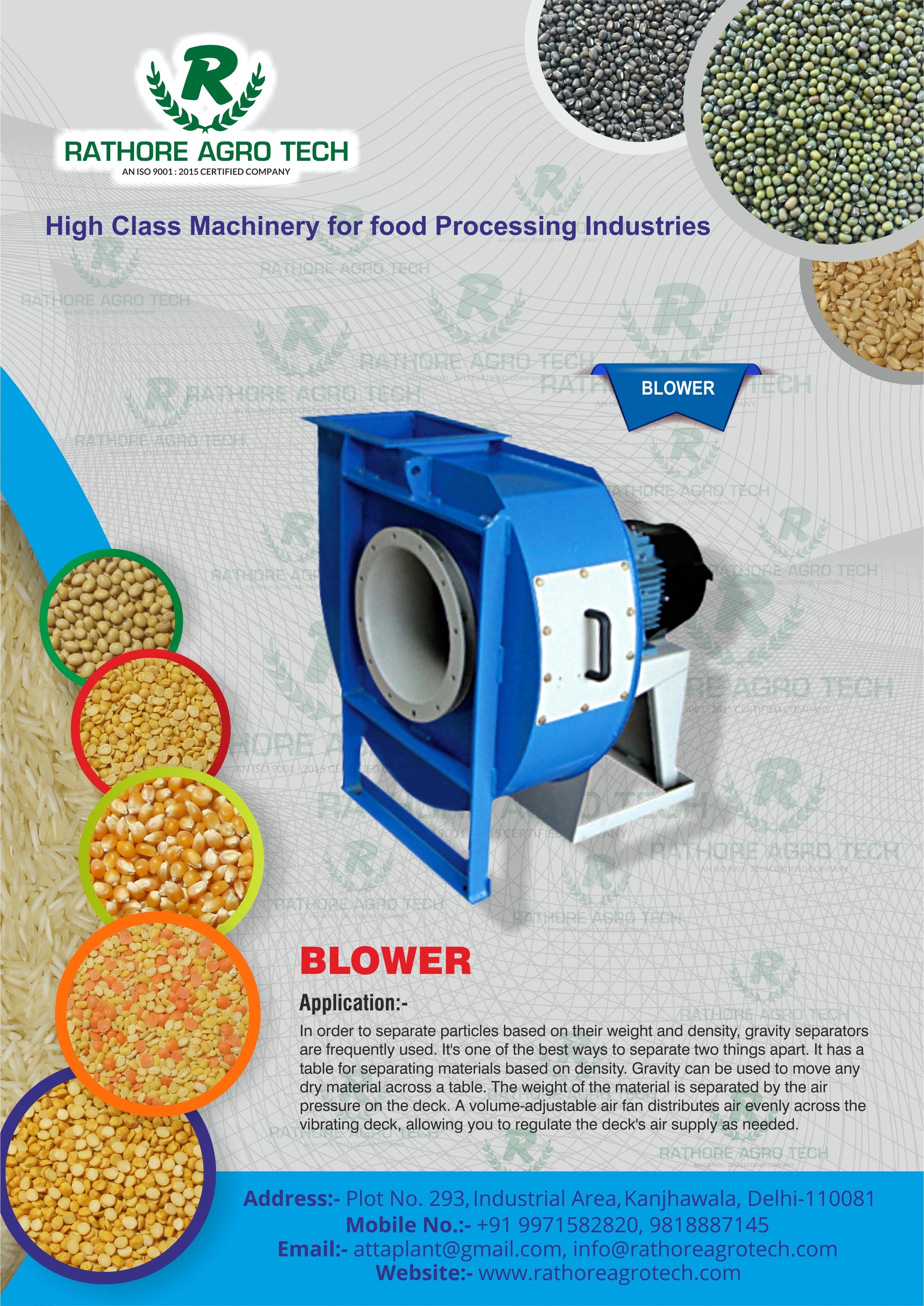

Durable Stainless Steel Build with Colorful AppealConstructed from premium stainless steel and presented in a striking blue color, the centrifugal fan offers exceptional corrosion resistance and visual distinction. Its lightweight design, ranging from 25 to 50 kilograms, ensures easy installation and adaptability to various milling setups, while the stainless steel material guarantees longevity in rigorous use.

FAQs of Centrifugal Fan:

Q: How does this centrifugal fan improve the roller milling process?

A: The fan ensures a consistent airflow, which helps in efficient separation and cleaning in the sifter system of roller mills. This results in enhanced product quality and increased processing efficiency during wheat milling.

Q: What are the main benefits of using a stainless steel centrifugal fan in industrial applications?

A: Stainless steel construction provides excellent durability and resistance to corrosion, making the fan suitable for continuous use in industrial environments like wheat processing, where hygiene and longevity are essential.

Q: When should I expect maintenance on this centrifugal fan?

A: Routine maintenance is recommended as per your mills operational schedule or according to the manufacturers guidelines, even though the fan is built for reliable, automatic operation. Regular checks can optimize longevity and performance.

Q: Where can this centrifugal fan be installed within a roller mill setup?

A: It can be conveniently integrated wherever airflow is required for cleaning systems or dust extraction within a roller mill, thanks to its compact build and flexible voltage compatibility.

Q: What is the process for installing the centrifugal fan?

A: Installation involves mounting the fan in the designated area of your roller milling system, connecting it to the appropriate power supply (220V, 380V, or 420V), and configuring the PLC control to match your mills operational parameters.

Q: How is this fan operated given that it is computerized but not computerized?

A: The fan uses a PLC-based control system for automation, ensuring user-friendly operation without the complexity of a full computer interface, providing efficiency with simplified controls.