About Gravity Separator 5-10 TON PRE HR.

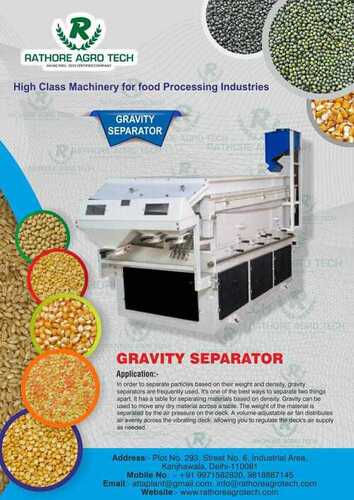

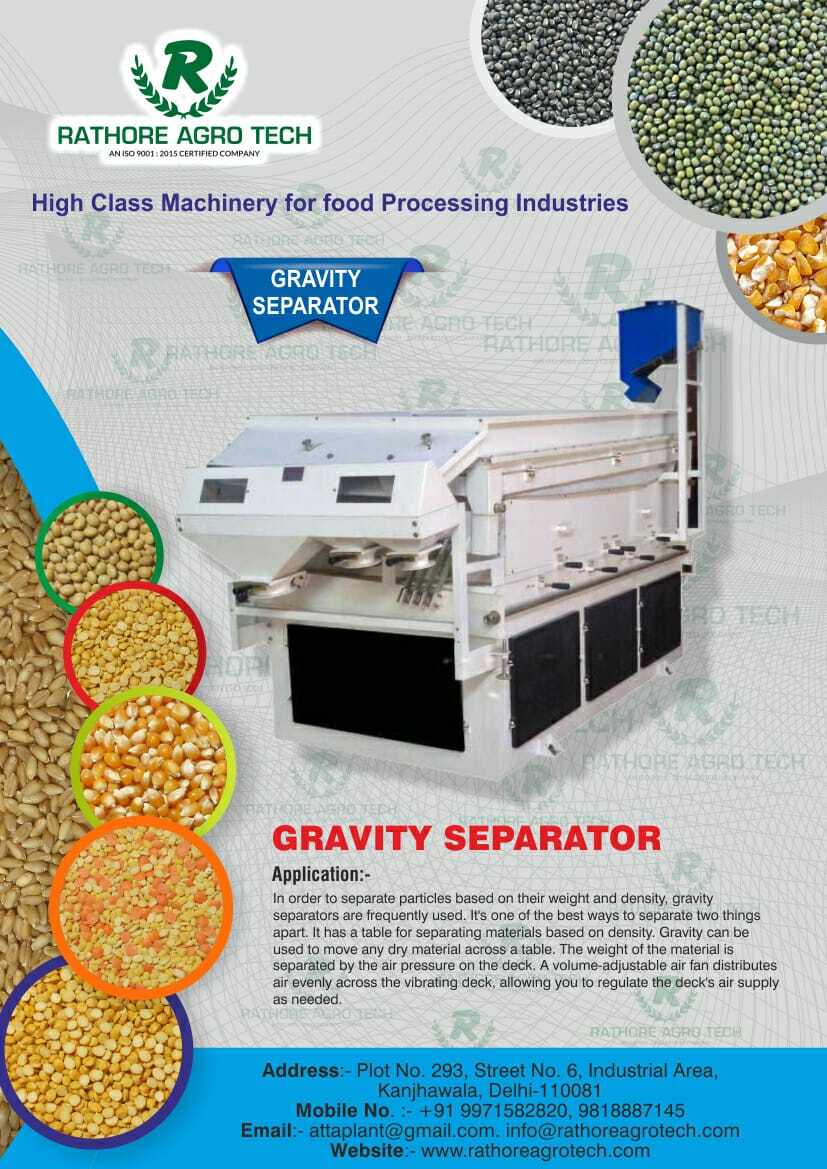

Gravity Separator

is a high performance food processing industrial unit that can be used in medium to large scale food and beverage industries to remove impurities from granular and powdered food substances. It is equipped with high performance electrical drives that run at standard alternating voltage to ensure controlled operation. The machine frame is fabricated by using mild steel that imparts high tensile strength to withstand extreme operational conditions. Gravity Separator manufactured and supplied by our company can be delivered to our clients as per their demands with the assurance of fast and safe delivery at a reasonable price.

Precision Sorting for Multiple MaterialsEngineered for high performance, the Gravity Separator 5-10 TON PRE HR efficiently separates and grades a variety of materials including cereals, seeds, grains, pulses, spices, and industrial products. Its adjustable design and stainless steel deck ensure accurate density-based sorting, making it an essential tool for diverse processing industries.

Efficient and Reliable OperationWith a robust vibration motor drive and adjustable feed rates, this gravity separator provides stable and consistent separation processes. The powder-coated mild steel body enhances durability, while the machine's operating noise remains under 75 dB, ensuring a safer working environment.

FAQ's of Gravity Separator 5-10 TON PRE HR.:

Q: How does the Gravity Separator 5-10 TON PRE HR operate?

A: This separator uses a vibration-driven, adjustable perforated stainless steel deck to separate materials by density. Feed and airflow rates can be fine-tuned, allowing precise and efficient separation of cereals, grains, spices, pulses, and industrial materials.

Q: What types of materials can be processed with this gravity separator?

A: The machine is suitable for processing a wide range of products, including cereals, all types of seeds, grains, spices, pulses, and industrial materials, thanks to its adjustable settings and robust construction.

Q: When should the deck adjustments be made for optimal performance?

A: Deck adjustments should be made when changing material types or when experiencing variations in feed rate or sorting efficiency. This allows the operator to maximize separation quality for each unique product batch.

Q: Where is this gravity separator typically installed and used?

A: It is commonly installed in seed processing plants, food grain mills, spice processing units, and industrial material sorting facilities. Its standard size and design make it suitable for a variety of commercial processing environments across India.

Q: What benefits does this separator offer compared to conventional methods?

A: The machine achieves up to 98% sorting efficiency, reduces manual labor, allows high throughput (up to 10 tons/hr), operates quietly, and offers durable construction with after-sales support. These features contribute to better product quality and operational savings.

Q: How is after-sales service provided for this gravity separator?

A: After-sales service is available from the manufacturer and accredited suppliers, ensuring regular maintenance, technical support, and prompt resolution of operational or mechanical issues.