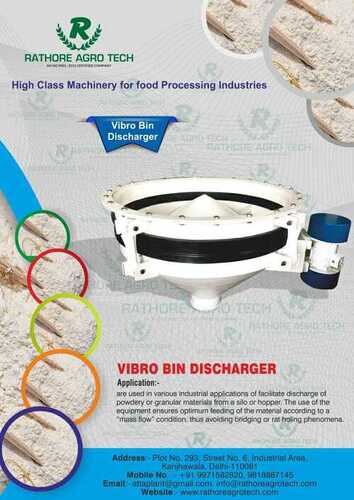

About Vibro Bin Discharger

Discover the Vibro Bin Discharger a featured, top-notch solution for efficient material flow in industrial settings. This exclusive machine is crafted from premium stainless steel for unmatched durability and comes in a sleek white finish. With fully automatic PLC control and ultimate cleaning via a sifter system, it guarantees decorated performance across milling operations. Proudly manufactured, supplied, and traded by a respected Indian company, this discharger is a must-purchase for optimum results. Enjoy a 1-year warranty assurance, making this an ideal investment for general industrial use.

Versatile Construction and Usage

The Vibro Bin Discharger excels in various industrial environments, designed specifically for robust use. Made from stainless steel, it ensures enduring quality and resistance to corrosion. This machine is suitable for tasks involving bulk material handling, particularly in flour mills equipped with plansifters. Its automatic operation and efficient sifter-based cleaning system make it ideal for continuous use, delivering reliable performance in demanding conditions.

FOB Port, Market Reach, and Certifications

When you finalize the purchase, handover of the Vibro Bin Discharger typically takes place at leading Indian ports such as Mumbai or Chennai. Our drop-off process is streamlined for international clients, with an asking price reflective of top-tier specification and certification standards. We actively export to major regions including Asia, Middle East, and Africa, affirming our compliance with rigorous industry certifications for peace of mind.

FAQs of Vibro Bin Discharger:

Q: How does the Vibro Bin Discharger improve industrial material handling processes?

A: The Vibro Bin Discharger enhances the efficiency of material flow by utilizing vibration to gently discharge bulk materials from bins or hoppers. Its PLC-controlled automatic operation reduces manual intervention, minimizes blockages, and promotes a consistent flow.

Q: What materials is the Vibro Bin Discharger suitable for?

A: This machine is ideal for handling a broad range of bulk powdered and granular materials, particularly in flour milling operations utilizing plansifters. Its stainless steel build supports applications requiring hygienic and corrosion-resistant solutions.

Q: When should the Vibro Bin Discharger be maintained or serviced?

A: Regular inspection and cleaning are recommended per the manufacturers guidelines, though the integrated sifter-based cleaning system minimizes extensive maintenance. Annual servicing is advised to ensure optimal operation and maintain warranty validity.

Q: Where is the Vibro Bin Discharger commonly installed?

A: It is commonly used in flour mills and similar industrial facilities where controlled discharge of materials from bins or silos is required. The white stainless steel construction allows it to fit seamlessly into modern production plants.

Q: What benefits does the exclusive stainless steel build offer?

A: The use of high-grade stainless steel provides superior durability, resistance to wear and corrosion, and ease of cleaning, making the Vibro Bin Discharger an ideal choice for industries demanding robust and hygienic handling equipment.

Q: How do I initiate the purchase process and what certifications are provided?

A: To purchase, you may contact us directly as a manufacturer, supplier, trader, or wholesaler in India. We support a smooth handover at the designated FOB port and provide all necessary export certifications ensuring compliance with international quality standards.