About Centrifugal Blower

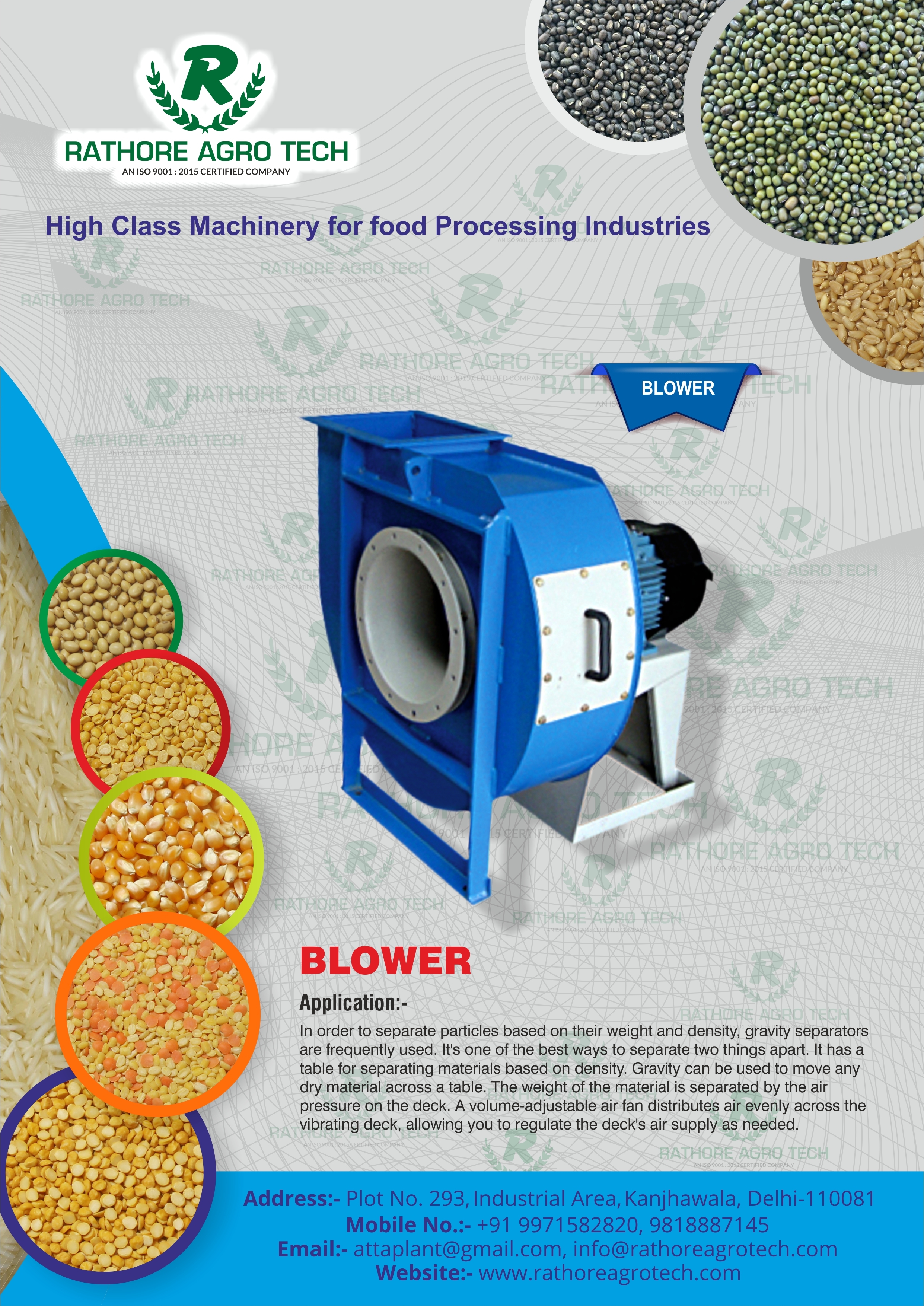

Blower

Die cast aluminum made Blower is used as integral equipment in food processing field. Driven by electricity, this machine has IP55 protection rating. With having F class insulation rating, this machine is appreciated for its high speed operation. It consists of necessary parts like blow and suction vacuum, compressor and burst proof motor. This equipment is reckoned for its energy efficient operation, compact shape, maintenance free functioning and low noise operation. It has standard pressure level, vacuum range and air flow level. This machine has low downtime rate and it is quite easy to operate. We are a successful trader and manufacturer of Blower.

Advanced PLC Control for PrecisionEquipped with a Programmable Logic Controller (PLC), this centrifugal blower ensures precise monitoring and automated adjustment during maize processing. The advanced technology reduces human error, optimizes operational efficiency, and guarantees consistent product quality, supporting a wide range of industrial requirements.

Hygienic and Efficient DesignMade from stainless steel and featuring an integrated sifter cleaning system, the blower provides superior hygiene and easy maintenance. Its automatic cleaning capabilities decrease downtime and ensure uninterrupted processing, meeting industrial standards of safety and sanitation for food-grade applications.

Versatile Industrial ApplicationsWith a capacity to process between 500 and 6000 kg of maize per day, this blower is ideally suited for a variety of industrial settings. It serves as an invaluable asset for manufacturers, suppliers, and traders seeking scalable and reliable maize handling solutions.

FAQs of Centrifugal Blower:

Q: How does the PLC control system enhance the operation of the centrifugal blower?

A: The PLC (Programmable Logic Controller) control system enables automated and precise management of the blower, optimizing performance, reducing manual intervention, and ensuring consistent operation during maize processing.

Q: What benefits does the stainless steel construction offer for industrial maize processing?

A: Stainless steel provides excellent durability, corrosion resistance, and easy cleaning, making it ideal for processing maize in hygienic industrial environments. It extends the blowers lifespan and maintains food safety standards.

Q: When is the automatic sifter cleaning system activated, and how does it work?

A: The automatic sifter cleaning system operates during and after processing cycles, removing accumulated debris and ensuring the blower remains free from blockages. This automated process minimizes maintenance time and enhances efficiency.

Q: Where can this centrifugal blower be utilized most effectively?

A: This blower is best suited for industrial settings such as food processing plants, maize milling facilities, and agro-industries, particularly across regions in India that require reliable and large-scale maize handling solutions.

Q: What is the process for using this blower in maize processing operations?

A: To use the blower, operators load raw maize and initiate the automated PLC system. The machine processes the maize efficiently, and the sifter ensures consistent cleaning throughout, resulting in streamlined and sanitized operations.

Q: What are the primary usage benefits for manufacturers and traders?

A: Manufacturers and traders gain from reduced labor requirements, increased throughput, improved hygiene, and stable daily capacities ranging from 500 to 6000 kg, making operations more productive and cost-effective.