About 5 - 10 Ton per Hour Vibro Grader

Vibro Grader

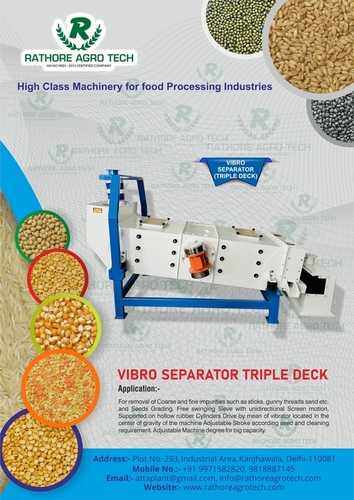

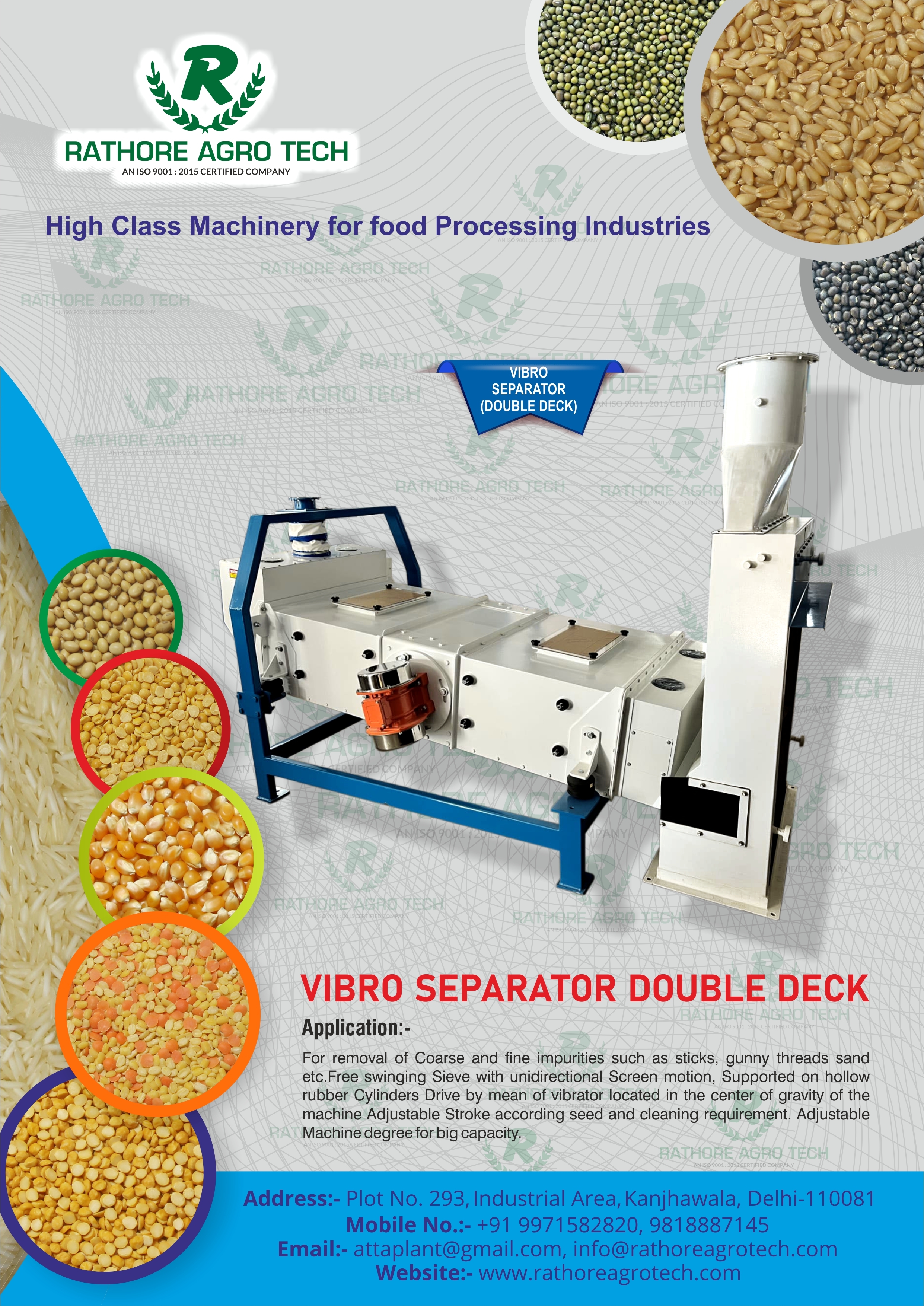

Vibro Grader is utilized for grading and screening of grains and seeds. This machine is equipped with dual vibration motors. Outer structure of this machine is made of stainless steel or carbon steel. It consists of multiple decks and its voltage level can be adjusted as per local power supply condition. This machine is offered with standard components like basement support, vibration motor, special feeding hole and acoustically insulated basement. Excellent screening performance, adequate sieving space, standard screening angle and adjustable voltage are the features of this machine. We are a prestigious manufacturer and supplier of standard grade Vibro Grader.

Exceptional Grading CapacityDesigned to handle 5 to 10 tons per hour, this Vibro Grader excels in environments demanding high throughput. It offers precise separation and grading, making it the ideal choice for industries where consistency and speed are paramount.

Efficient Energy UsageOperating at just 300 watts, the Vibro Grader delivers outstanding results while minimizing energy consumption. This efficiency reduces operational costs and supports businesses in pursuing sustainability goals without compromising performance.

Reliable Industrial PerformanceWith its solid construction and weight range of 400-800 kg, this grader ensures stability and durability even during prolonged use. It is widely used across various industrial settings, offering dependable operation to manufacturers and suppliers throughout India.

FAQs of 5 - 10 Ton per Hour Vibro Grader:

Q: How does the Vibro Grader function in an industrial setting?

A: The Vibro Grader operates by utilizing vibration technology to efficiently separate and grade materials based on size or other criteria. This ensures consistent results, making it suitable for industrial processing lines where reliable and rapid sorting is essential.

Q: What are the main benefits of using this Vibro Grader?

A: Key benefits include high capacity (up to 10 tons per hour), energy efficiency with a low 300-watt requirement, and robust construction for long-term use. It enhances productivity, assures consistent output, and reduces operational expenses.

Q: When is it advisable to use this type of grader?

A: This Vibro Grader is recommended for use when you need to process and grade large volumes of materials quickly and accurately, particularly in industrial or manufacturing applications demanding efficiency and precision.

Q: Where can I source the 5-10 Ton per Hour Vibro Grader in India?

A: Manufacturers, suppliers, traders, and wholesalers throughout India offer this Vibro Grader. You can contact reputable industrial equipment providers to find this machine tailored to your requirements.

Q: What is the typical process for installing and operating the Vibro Grader?

A: Installation involves securely placing the grader on a level surface, connecting it to a suitable power source (415 output), and following the manufacturers operational guidelines. Basic training for staff is recommended to ensure safety and optimal use.

Q: How is the Vibro Grader utilized for daily industrial tasks?

A: The grader is typically used as part of an assembly line to grade and separate bulk materials by size or type, enhancing workflow and ensuring quality control in the processing stage.