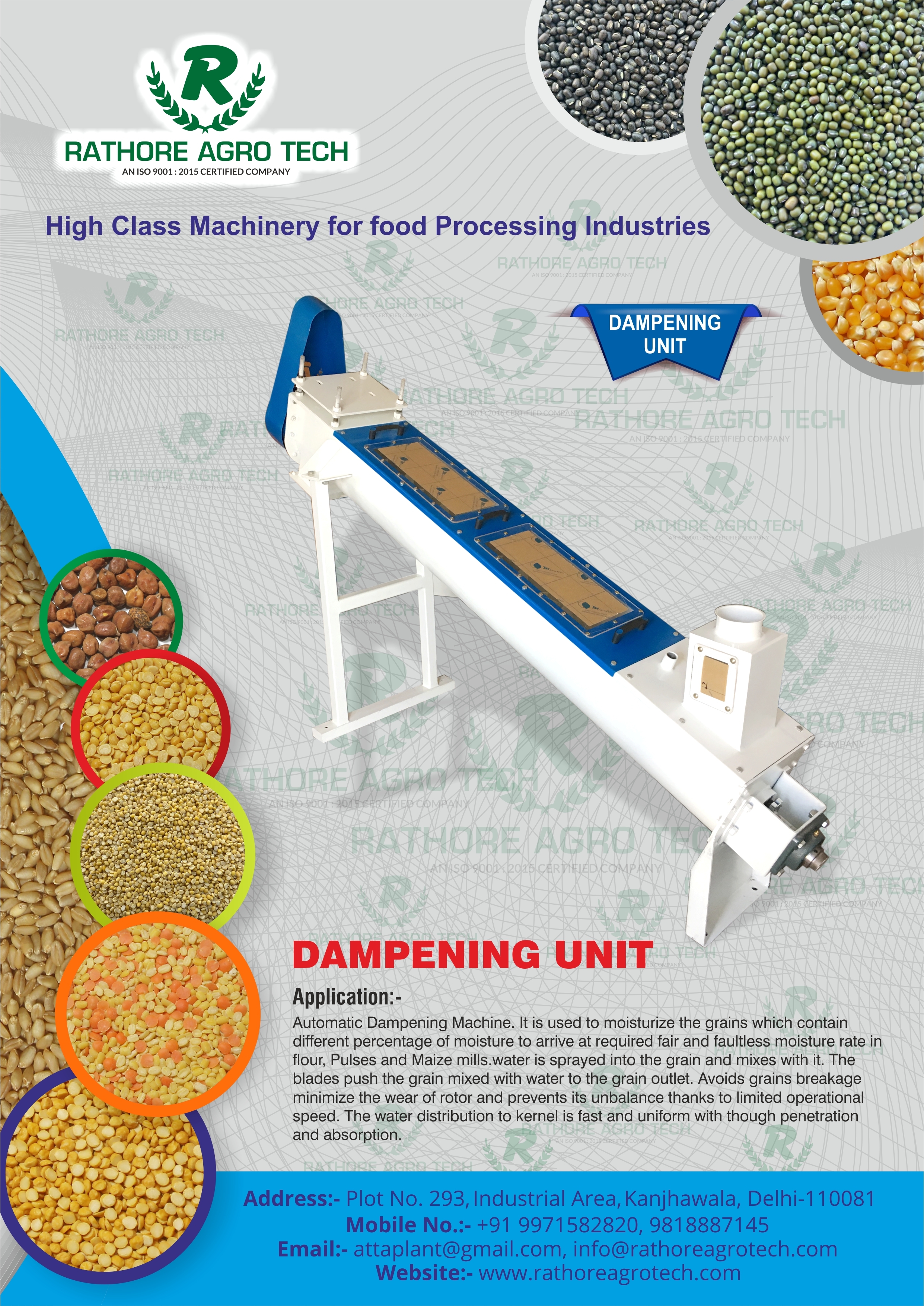

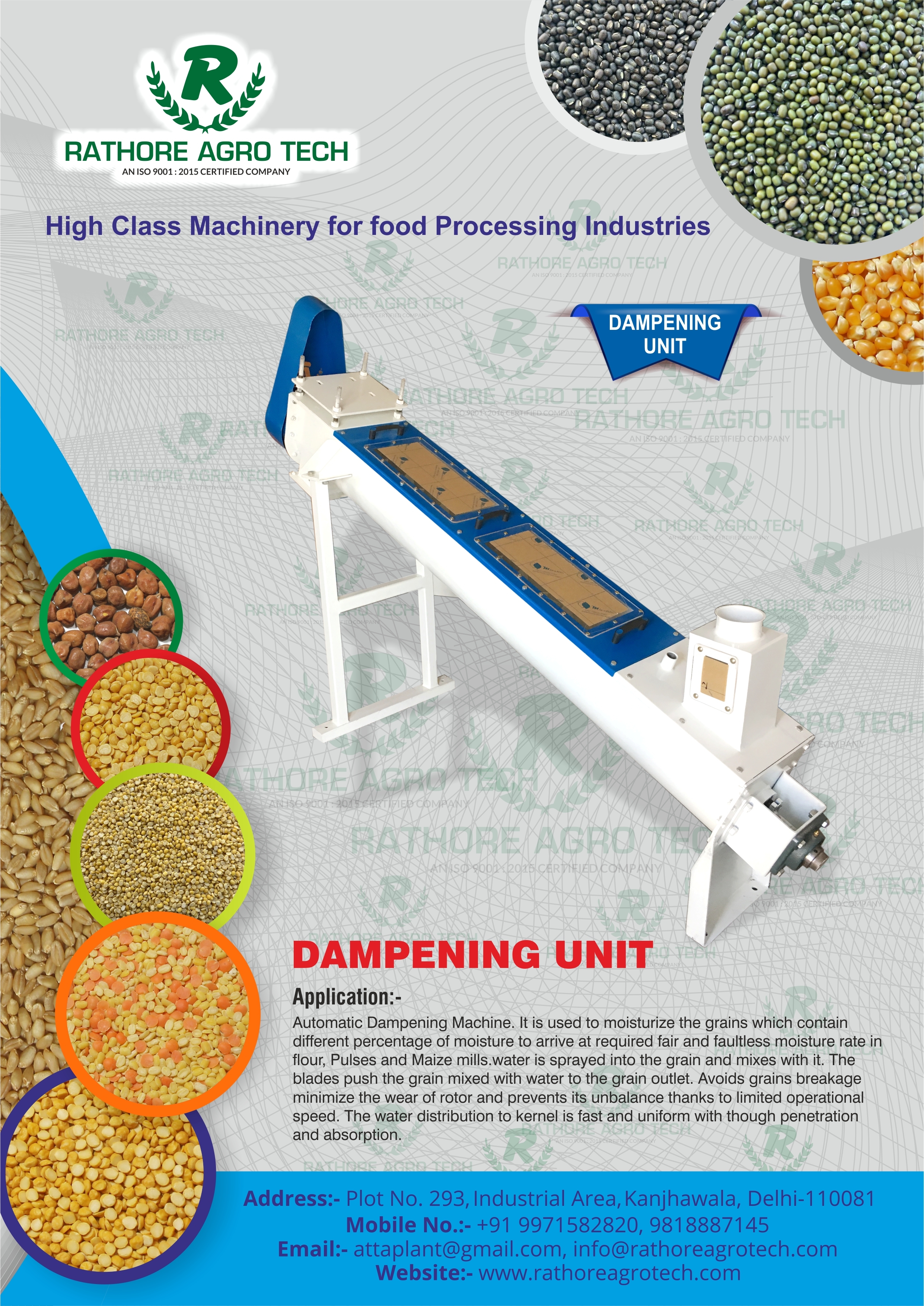

About Dampening Unit Paddle Type

Explore the potential of wheat processing with our Dampening Unit Paddle Type, a pivotal innovation for flour milling facilities. Fabricated from valorous stainless steel and featuring a robust roller milling system, this scarce and sought-after unit stands out with its integrated sifter and advanced cleaning system. PLC control ensures precision across industrial applications, while a one-year warranty underscores durability. Non-automatic by design to offer greater control, its white finish embodies both hygiene and modernity. Grab this essential manufacturer-supplied solution-available for traders, wholesalers, and suppliers across India-for elevating productivity and output quality.

Applications and Features of Dampening Unit Paddle Type

The Dampening Unit Paddle Type is extensively used by industrial wheat milling operations seeking consistent moisture distribution. Its robust stainless steel build, combined with a cutting-edge cleaning system and integrated sifter, make it ideal for handling wheat as the primary media. Essential features include a PLC control system for reliable process management and a non-automatic design that maximizes operator oversight. This unit is a perfect fit for industries wanting efficient, cost-effective wheat pre-processing solutions.

Export, Certifications, and Arrival Processes for Global Markets

Order processing for the Dampening Unit Paddle Type is streamlined with prompt FOB (Free On Board) dispatch from major Indian ports. Arriving with a suite of industry certifications, it assures global buyers of premium quality and safety standards. Our main export markets span Africa, Asia, and the Middle East, reflecting the unit's worldwide appeal. Each shipment is handled with care, prioritizing timely arrival and customer satisfaction from inquiry to delivery.

FAQ's of Dampening Unit Paddle Type:

Q: How does the cleaning system in the Dampening Unit Paddle Type function?

A: The cleaning system uses paddles and an integrated sifter to efficiently remove contaminants from wheat before it enters the milling process, ensuring high product purity.

Q: What are the primary benefits of using a paddle-type dampening unit for wheat processing?

A: Using this unit ensures uniform moisture content in wheat, resulting in improved milling efficiency, better flour quality, and reduced operational downtime during processing.

Q: When should a facility consider upgrading to a PLC-controlled dampening unit?

A: Facilities should consider upgrading when they require greater process precision, data monitoring, and consistent control over moisture addition for optimal flour production results.

Q: Where is the Dampening Unit Paddle Type manufactured and supplied from?

A: This unit is manufactured, supplied, and traded in India, making it accessible for domestic buyers and global markets requiring premium industrial equipment.

Q: What is the typical process for order placement and delivery of this equipment?

A: Orders can be placed directly with the manufacturer or authorized suppliers. After confirmation, order processing proceeds to dispatch via FOB Indian ports, ensuring prompt and secure international shipment.